June 10/17, 2019: Volume 34, Issue 26

By Lindsay Baillie

The resilient flooring category is on course to have another stellar year of growth, thanks in part to the excitement surrounding WPC and SPC products.

The resilient flooring category is on course to have another stellar year of growth, thanks in part to the excitement surrounding WPC and SPC products.

However, some resilient manufacturers say much of the new growth will stem from SPC instead of WPC sales. As WPC gets its own dose of cannibalization, SPC is expected to continue taking market share from just about everywhere and every product category.

“Rigid core is taking share from almost all hard surface sectors,” said Derek Welbourn, CEO, Inhaus. “Its growth is clearly due to it being a great product, but also because it is a great fit for a lot of uses, from commercial to any room in a residential space.”

Isaac Lee-San Leandro, branch manager, Eternity, saw the strength of rigid core firsthand when the company launched its SPC collections. “We were anticipating that it would do very well. However, we did not expect it to grow so rapidly and seize the entire resilient flooring category. It has become the top choice in resilient flooring luring many consumers away from other flooring categories such as carpet, laminate and hardwood mainly because of it being a 100% waterproof product.

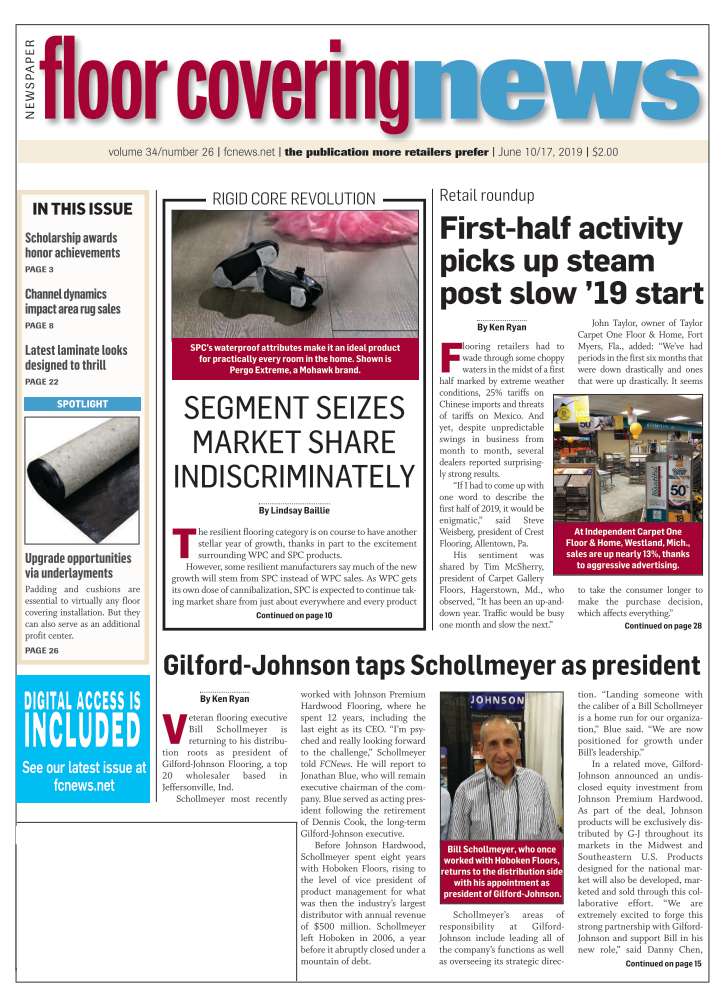

Residentially, SPC’s waterproof attributes make it an ideal product for practically every room in the home, manufacturers say. Bedrooms, bathrooms, living rooms, kitchens, basements, laundry rooms, mud rooms, home offices and even gyms are all taking part in the rigid revolution—and for different reasons.

“Rigid offers a waterproof floor that does not trap dirt and offers hypoallergenic properties,” said Michael Raskin, president, Raskin Industries. “Carpet is now being taken out and replaced with new, fresh rigid visuals offered in wood, stone and textile looks.”

Flooring executives, such as Ed Sanchez, vice president of product management, Mohawk and the Pergo brand, also see rigid’s latest visuals as a key to its success. “Rigid core is taking share from across the board,” Sanchez said. “Because of the improvements of visuals, rigid has made its way into bedrooms and other spaces previously reserved for carpet.”

While SPC’s expansion throughout the entire home can be attributed to its durability and waterproof attributes, experts believe the latest digital printing technology has made it hard for other hard surfaces to compete. “The advancements in digital print and embossing technologies are creating some of the most realistic, beautiful floors available, and in many cases at a fraction of the price of the real thing,” said Art Layton, director of specialty products, Axiscor Performance Flooring.

Mike Belprez, director of product management and innovation, Cali, sees the aggressive growth of rigid products as a “lifestyle takeover.” The product attributes, he noted, are more appealing than ever and have resonated with the consumer. “Many who had never before considered vinyl floors now opt in based on these key selling features that allow homeowners to live on their floors with assurances of lasting quality and performance.”

While WPC has been relegated to mostly residential and light commercial applications, manufacturers say SPC is making a greater dent in commercial, with the potential of cannibalizing WPC in light-commercial settings.

“COREtec’s patented original WPC flooring helps a house look and feel like home,” said Kathy Young, vice president, marketing, USFloors. “This innovative flooring provides an unmatched combination of beauty, durability, comfort and sound-dampening performance. We also developed our SPC floors to provide extra strength and rigidity to meet the demands of commercial and high-traffic residential applications.”

SPC’s qualities make it ideal for several commercial sectors with high traffic. “SPC resists indentation and high impact, making it an excellent choice for commercial applications,” said Jeff Francis, hard surface resilient category director, Shaw Floors.

CFL, which has also been making some noise in the rigid core arena, is seeing a significant uptick in commercial applications such as hotels and restaurants. “While the growth is taking share from all sectors, we also think a side benefit is the popularity and simplicity of rigid products is also shrinking the replacement cycle for flooring,” said Thomas Baert, president.

Manufacturers such as MSI are seeing rigid core products taking over in hospitality. “It is gaining tremendous momentum and popularity, due to how beautiful, resilient and fast they are to install and maintain,” said Sam Kim, senior vice president.

Other suppliers, including Karndean Designflooring, sees rigid making headway in multi-family applications. “Rigid core has grown popular in the entire residential sector, but specifically in upper-level rooms that require acoustic qualities, like playrooms or children’s bed- rooms,” Bill Anderson, CEO, told FCNews. “Commercially, we anticipated rigid core would be popular within multi-family for the same reasons as the residential market, but  we’ve seen our rigid core enter all the commercial segments. That’s due in part to acoustics and because our rigid core products exceed the ASTM standard for indenta- tion resistance and dimensional stability.”

we’ve seen our rigid core enter all the commercial segments. That’s due in part to acoustics and because our rigid core products exceed the ASTM standard for indenta- tion resistance and dimensional stability.”

Cali’s Belprez sees rigid emerging in Main Street applications. “Ease of install, light to heavy commercial ratings and modern visuals make it an ideal solution.”

While rigid is making its way into commercial, most manufacturers do not see it capitalizing on the market. “These click formats are a perfect solution for residential living spaces, but because of heavy rolling loads, specifically, commercial spaces perform best when directly glued,” said Amy Tucker, senior marketing manager, Philadelphia Commercial. “Traditional/flexible glue-down LVT is typically great for new construction and where subfloors are perfectly smooth but can cause problems later if installed over a subfloor with imperfections. Last year, Philadelphia Commercial introduced products featuring Advantium Core and continue to add to our portfolio. These products were developed to address these issues.”

SPC vs. everything else

As the industry’s latest darling product, it is no surprise that SPC is taking market share from almost every flooring category—including other resilient products. The reason, experts say, is because of rigid’s various attributes and visuals.

“Rigid has been impacting products across hard and soft surface,” Mohawk’s Sanchez explained. “For instance, when you think about tile, people are moving toward rigid because of its dent resistance and inability to chip. When you think about wood, those with an active lifestyle are moving toward rigid because of that dent resistance along with its waterproof feature. Rigid delivers embossed-in-register looks that provide more realism—even better than real looks—that attract people who are fashion-conscious and are looking for unique designs.”

The beauty of rigid core, according to Yon Hinkle, director, product design and innovation, Armstrong Flooring, is it combines some of the greatest features from multiple flooring categories. “First, rigid core flooring can bring to life the exacting detail of natural wood looks, and it is built to maintain its beauty—even under high traffic, high moisture and high impact. Second, the construction of rigid core includes a dense, solid core that hides subfloor irregularities and provides superior resistance to indentation, an important consideration to help keep floors looking newer longer. Third, thanks to its dimensional stability, installers do not have to acclimate rigid products in most installations.”

According to Jimmy Tuley, vice president, residential resilient business, Mannington, LVT and rigid products no longer have a plastic/PVC look, and that has increased its appeal. “That was one of the hurdles the industry had to get over,” he explained. “Now that it has, there are performance features such as the waterproof nature, the durability of it, the ease of installation that people really like. The locking systems are very easy to install. They don’t require glue or a lot of tools—it has really solved a lot of technical problems for installers as well.”

Bret Perkins, vice president, hard surfaces, Southwind, sees all products being impacted by varying degrees. However, lower price-point categories are taking the biggest hit. “With the innovation of SPC, we are starting to see more realistic, embossed visuals,” he noted.

Bret Perkins, vice president, hard surfaces, Southwind, sees all products being impacted by varying degrees. However, lower price-point categories are taking the biggest hit. “With the innovation of SPC, we are starting to see more realistic, embossed visuals,” he noted.

Among hard surfaces, hardwood and WPC are beginning to feel pressure from SPC, according to Chris Dillion, vice president of sales and marketing, Celeste. He believes hardwood sales are down this year as a result of rigid core’s growth. “When it comes to rigid core eating into the WPC, it is for two reasons. For one, rigid core is more waterproof than WPC. In markets like Florida, for example, we have seen three years’ worth of moisture in a home actually catch up to the WPC and make it buckle. This is because WPC still has wood in its core and the wood over the course of a few years will take in water; rigid core will not.”

The second reason, Dillon notes, is SPC is cheaper to manufacture. “You are getting the exact same look but for much less money.”

Beyond hardwood, observers also see rigid stealing market share from ceramic tile and carpet. Proponents cite rigid’s look, performance and price point. “It’s the marriage of form and function,” said Jason Hair, vice president, Phenix.

Other industry experts, including Kurt Denman, chief marketing officer and executive vice president of sales at Congoleum, also believe ceramic/porcelain and laminate have lost share to SPC. But it’s resilient sheet that has likely been impacted the most.

“Over the past several years, there has been plenty of consternation throughout the industry over the lack of qualified installers,” Denman explained. “And while our AirStep products, with multiple installation options, is certainly one of the easiest to install, a 12-foot roll of flooring can be intimidating. However, resilient sheet continues to be an incredible value. The designs are truly awesome and it’s seamless and actually 100% waterproof.”

A major reason for rigid core’s success, observers say, is it solves a lot of challenges for the consumer. As CFL’s Baert explained. “It can be installed over most existing floors. It is low maintenance and can be wet-mopped. And, with increasing innovation providing differing widths, lengths,

embossed-in-register, etc., consumers can get the look they want at a price they can afford in a product that performs well in the home.”

As rigid core continues to evolve and improve, most manufacturers expect the category to continue stealing growth. “It started with WPC and has expanded to include SPC and HDPC,” said Steve Wagner, director of sales and marketing, Wellmade. “At the end of the day, rigid core is a superior flooring product that represents a better mousetrap that will continue to impact all flooring categories well into the future.”

Tariff trouble

Most manufacturers believe the aggressive growth of the rigid category has a slim chance of slowing down, even despite the impending tariffs on Chinese imports. While flooring executives are split on whether or not the tariff is necessary, most agree it will have a small—mostly undetectable—impact on the consumer.

“The rigid core market does not show any slowdown anytime soon,” said Nick Brown, vice president sales – North America, Beauflor USA. “With the expected continued growth, the challenge for manufacturers and distributors will continue to be the number of rigid core products that are offered to the market. At Beauflor, with all the continued tariff discussions, we continue to aggressively market our Made-in-Belgium Pure rigid core product. Having a European-manufactured rigid core product that has a unique, four-sided Dreamclick locking system gives our customers a product that will stay consistent and competitive with regards to price.”

Kelley Bolas, senior product manager, LVT, Tarkett North America, echoed Brown’s sentiments. “The trend of solid rigid core will not slow down soon. The tariff will have some effect on the pricing of current solid rigid core products, but as technology is enhanced, pricing will level out.”

Kelley Bolas, senior product manager, LVT, Tarkett North America, echoed Brown’s sentiments. “The trend of solid rigid core will not slow down soon. The tariff will have some effect on the pricing of current solid rigid core products, but as technology is enhanced, pricing will level out.”

Industry executives like Jamann Stepp, vice president hard surface, The Dixie Group, believes rigid core will represent 50% of the resilient category—approximately $2 billion in wholesale revenue—by the end of 2020. “However, if the tariff remains at 25% long term [deep into 2020], we may see a slight slowdown in overall volume. Nonetheless, even with a slight downward tick in volume, rigid core will still be the growth engine not only for the resilient category, but rigid core will continue to be the growth engine for hard surface and for the flooring industry.”

Denman views WPC and rigid core as “slight iterations of the same,” remarking that as more versions are created it will continue to command more share of the market until something with even better performance or price, or easier installation methods, takes its place. “It’s exactly what is happening between WPC and rigid core right now,” he explained. “The performance attributes are nearly identical, but rigid core has a price advantage.”

In terms of tariffs, Denman sees the added cost as a positive. “One of the benefits of the tariffs has been a narrowing of the price gap between imported and domestically produced goods. If we’re honest about it, the single greatest benefit of any of these import products has been price.”

Others feel the tariff levels the playing field for other countries such as Korea and the U.S. “The tariffs have more of a direct impact on big box or DIY markets,” Raskin explained. “The retail distribution model should be less effected as this customer is looking for other services other than a low price. This consumer desires customized service, quality and design. It will come down to the companies that offer the best design, service and quality attached to a marketing program that relates to today’s consumer.”

Cali’s Belprez does not believe tariffs will impact the growth of SPC. However, he does see it affecting how products will be sourced. “A product that is predominantly sourced in China will surely drive manufacturers and importers to find partners outside of China,” he explained.

Mannington’s Tuley also sees the tariffs as an issue for companies solely manufacturing in China. “I think U.S. rigid manufacturing will become a premium. We’re excited to be getting into that game as we build our rigid plant in Georgia. And I think the market overall will respond with cost reductions and efficiency improvements to keep the tariff impact to a level where we can continue to show a value with these products above other products.”

Of course, this is all contingent upon importers playing by the rules. (According to a recent USA Today article, China is intentionally mislabeling its products as “Made in Vietnam’ to avoid U.S. tariffs. How it works: Chinese firms first export products to Vietnam, then change the labeling on packages before exporting the goods to the United States, Japan or Europe, officials said. Vietnamese officials are calling for more aggressive examination of the certificates of origin of several product categories, which include steel, aluminum, textiles and processed wood products.)

While the tariffs pose an immediate issue for manufacturers and flooring dealers, consumers probably won’t feel the impact, Phenix’s Hair said. This is because flooring is generally a once-in-10-years purchase and consumers won’t know any different in terms of pricing, he explained.

Chet Graham, president, Marquis Industries, explained that while the tariffs could slow growth in the WPC/SPC category, it won’t be enough to create a stoppage. “Tariffs have become a usage tax and as long as consumers are willing to pay for this slight increase the category will still be viable in the marketplace,” he noted.

MSI see the tariffs impacting rigid core growth via the increased cost of the product, which must be passed on to American consumers. Second, residual impact from increased cost of other goods from China, which results in lowered consumer buying power to pursue repair and remodel activities that utilize rigid core flooring.