A critical component to the success of any floor covering installation is what lies underneath the product. Industry experts say a properly prepared subfloor will help prevent costly and time-consuming callbacks.

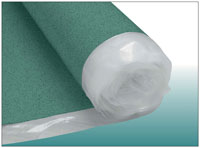

Most important is specifying an underlayment that meets requirements for the floor covering. That decision depends on such factors as sub- floor condition, flooring manufacturer’s guidelines and price. An installer and retailer should also be aware of manufacturer warranties.

Most important is specifying an underlayment that meets requirements for the floor covering. That decision depends on such factors as sub- floor condition, flooring manufacturer’s guidelines and price. An installer and retailer should also be aware of manufacturer warranties.

Underlayments are not designed to add structural integrity to a subfloor; they can only perform as well as the subfloor itself, industry members say. It is sometimes necessary to level an uneven subfloor to provide the best base for the flooring product. This includes removing wax or sealers, dust or dirt to ensure a lasting bond.

Soft and hardwood surfaces are considered “forgiving” products which can cover up subfloor imperfections such as holes and cracks. However, the majority of resilient flooring reportedly requires some type of subfloor preparation, because these products are thinner and shinier. This means there should not be any subfloor deviations greater than

1⁄8-inch. For subfloor preparation in existing structures, experts recommend concrete floors be cured, cleaned and free of moisture before applying underlayment. Wood subfloors should be well nailed and free of movement.

When preparing concrete slabs and wooden subfloors, installers can utilize either a self-leveling underlayment or a trowelable patching compound. According to industry members, determining which product to use depends on subfloor condition and room size.

Trowelable underlayments are usually specified for repairing subfloor irregularities in small areas. The product is spread with a trowel onto the subfloor in multiple layers. Often subfloor preparation will take two days, experts say, with flooring installed on the third day. This process creates a relatively smooth surface, although it may require sanding to eliminate minor bumps.

By comparison, self-leveling underlayment is a fast-drying liquid cement which can be installed up to 1⁄2-inch thick. The drying time for self-leveling underlayments ranges from three to 24 hours, experts say, depending on the product.

Industry members say the better wood underlayments are hard and provide a more solid base under the floor. In addition, they are reportedly more uniform in thickness from board to board, so there’s less of a chance joints will show through the new floor, which is called telegraphing.

-K.J. Quinn