Lancaster, Pa.—Ecore, a company that transforms reclaimed materials into performance products, has achieved environmental claim validations from Underwriters Laboratories (UL) for two of its manufacturing facilities.

Lancaster, Pa.—Ecore, a company that transforms reclaimed materials into performance products, has achieved environmental claim validations from Underwriters Laboratories (UL) for two of its manufacturing facilities.

Ecore recently partnered with UL to complete a 2020 Zero Waste to Landfill audit for its Pennsylvania-based facilities in Lancaster and York. As a result, UL has officially validated the following claims for these Ecore production sites:

- The Lancaster facility achieved a Landfill Diversion rate of 99%, with 22% waste diversion with energy recovery.

- The York facility achieved a Landfill Diversion rate of 100%, with 22% waste diversion with energy recovery.

“This is a huge milestone in our company’s pursuit of a more circular economy and a world free of rubber waste,” said Art Dodge III, CEO and president of Ecore. “We like to say that Ecore was born ‘green’ and, as an industry leader in recycled products technology, these validations reinforce our commitment to reducing our environmental impact.”

As the global safety science leader, UL said it helps companies to demonstrate safety, enhance sustainability, deliver quality and achieve regulatory compliance, while enhancing consumer confidence and peace of mind. According to the company, the UL Environmental Claim Validation Mark communicates to purchasers that products have been evaluated by an objective third-party and independently proven to have been manufactured and/or to perform in accordance with the manufacturer’s environmental claims.

UL said it uses scientific analysis to determine the accuracy of sustainability claims and products bearing the UL Environmental Claim Validation Mark must undergo routine audits and testing in order to retain their validation status.

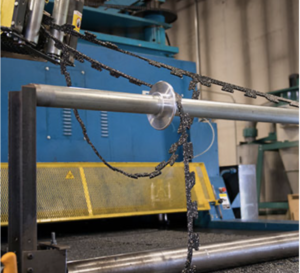

“Our products are manufactured in state-of-the-art facilities with a focus on continually improving efficiency, sustainability and responsible resource management,” Dodge said. “Furthermore, Ecore’s manufacturing process has virtually no waste–scrap material from production is collected and recycled back into our system because rubber can be continually recycled and does not degrade through the recycling process like other materials such as paper or plastics.”