By Reginald Tucker—The supply chain disruptions that have wreaked havoc on the U.S. flooring market—as well as scores of other industries across the country—have touched off a wave of repercussions. The most notable of which is record-breaking inflation as voracious consumer demand continues to outpace supply. This phenomenon is being felt more acutely in the U.S. market, which still relies on products manufactured outside America to feed the hungry beast that is consumer spending.

All this has once again put the spotlight squarely on the subject of reshoring—broadly defined as the return of manufacturing to America that had previously been outsourced to other countries. Reshoring has taken on a renewed sense of urgency as a result of supply-chain deficiencies initially exposed by the coronavirus pandemic and, subsequently, the crippling backlogs at many of the nation’s critical shipping ports. With scores of shipping vessels teeming with containers waiting for weeks on end to make their way to U.S. ports, the need for increased domestic manufacturing and investment has never been more dire.

“From a reshoring perspective it’s clear that government, consumers and companies must understand that a global and fractured extended supply chain is not good,” said Harry Moser, founder and president of the Reshoring Initiative, an organization whose mission is to bring millions of good, well-paying manufacturing jobs to the United States by helping companies more accurately assess their total cost of offshoring. “Reducing our dependence on foreign countries and corporations for critical technology and products is key. Quite simply, we need to source more in North America, with the U.S. getting the bulk of it.”

In the wake of the current backlogs at the nation’s critical shipping ports, many floor covering retailers and distributors who still rely on imported flooring products are having a difficult time fulfilling customer orders in a timely manner. For instance, it’s not uncommon for importers, distributors and dealers to wait three months or more for shipments to arrive into key U.S. ports. Once the shipments arrive, there’s the matter of landing a slot on

the dock to offload. And if that wasn’t enough, importers have to clear yet another hurdle because of the dearth of trucks and truck drivers required to move the product from the ports to their respective destina- tions inland.

But instead of canceling customer orders amid the long delivery delays, retailers are encouraging their distributors and manufacturing partners to provide local, U.S.-made alternatives, including domestically produced laminate flooring, hardwood, luxury vinyl tiles or planks—all of which are surging in popularity. And while several manufacturers have made significant headway in starting up their U.S.-based resilient operations, much of that initial capacity is being absorbed by large accounts such as national home centers and big box outlets, industry observers said.

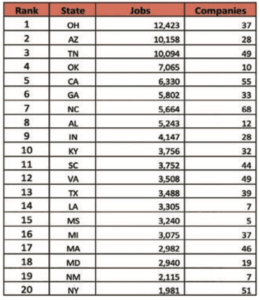

The upside, according to Moser, is the national reshoring effort is bearing fruit. Data compiled by the Reshoring Initiative showed companies brought back more than 200,000 manufacturing jobs to the U.S. last year. That’s way up from 6,000 onshored positions in 2010 and 160,000 in 2020. Still, Moser said he thinks there’s room for improvement. “While significant, this is still not enough growth needed to reduce the trade deficit and reach the goal of bringing back 500,000 jobs per year,” he stated. “Even if we reached that goal, we wouldn’t have the workers trained to handle the work at that pace.”

Despite the daunting challenges ahead, Moser still strongly encourages U.S. companies to bring production jobs back to the U.S. Many American firms, he noted, simply shifted production from China to other manufacturing centers across Asia, Mexico and South America as a means to avoid paying the tariffs and duties imposed on Chinese-made products during the previous administration. While cheaper labor costs in some of these locations have provided an incentive to outsource manufacturing, that “perceived” advantage is eroding. What importers and U.S.-based companies need to bear in mind, Moser stressed, are the rapidly rising costs associated with bringing in products from overseas—expenses that are essentially negating lower labor costs abroad.

To help U.S.-based companies, manufacturing executives and supply chain managers better assess their “true costs” of manufacturing locally vs. importing, The Reshoring Initiative has developed a tool called the TCO (Total Cost of Ownership) Estimator. How it works: Once users input their unique data into the calculator, they will receive their total cost of ownership analysis complete with: calculations of 30 cost factors for each source; an accumulation of all costs into cost categories; the TCO for each source; line charts showing each source’s current price and TCO; a five-year TCO forecast; and line charts showing their cumulative cost by category for each source.

What’s more, the TCO Estimator is recognized by the U.S. Commerce Dept. and, best of all, free to use. “Most companies make sourcing decisions based solely on price, oftentimes resulting in a 20%-30% miscalculation of actual offshoring costs,” Moser said. “The estimator helps companies account for all relevant factors—overhead, balance sheet, risks, corporate strategy and other external and internal business considerations—to determine the true total cost of ownership. Using this information, companies can better evaluate sourcing, identify alternatives and even make a case when selling against off-shore competitors.”

Users may access the TCO Estimator at reshorenow.org.