For decades, Canadian hardwood flooring brands have been associated with high quality—starting with the integrity of the raw materials that comprise the final product and extending throughout the fastidious approach suppliers follow during the manufacturing process. That hard-earned reputation continues today even in the face of competition both from outside and within the hardwood flooring category.

“Certainly the raw material represents an advantage, as most of the Canadian manufacturers—including us at Wickham—source Northern Appalachian lumber versus Southern Appalachian,” Paul Rezuke, the company’s vice president of sales, U.S., told Floor Covering News. “Another aspect that separates the Canadian suppliers is our tough grading standards, which tend to be stricter than a lot of our competitors. That means you’re starting out with better material from the beginning.”

Others attest to the quality of the materials many Canadian firms use. “For many of the manufacturers based here in Quebec, we’re able to use better raw materials to make the product, which we believe is superior to much of what’s out there on the street,” said Wade Bondrowski, director of sales U.S., Mercier Wood Flooring. “We’re proud to say we only pull our trees out of North America from the Pennsylvania region and farther north; it’s a slower-growing tree with fewer knots and mineral streaks and has a better coloration. In addition to that, the Northern oak tends to be a little more dense. Overall, it just mills better and is straighter and cleaner than some of the materials sourced from other regions.”

In other words, higher quality in, better products out. As Wickham’s Rezuke explained: “We find that a lot of our retailers and distributors—once they get the product into the market—tell us their customers typically come back and say, ‘That’s such a well-made product. That’s the one I want to use.’ It goes back to the combination of raw materials, grading and quality controls—all those factors contribute to the success of Canadian wood flooring manufacturers.”

Not resting on its laurels, Wickham Hardwood is looking to raise the stakes even higher. The company recently initiated a $14 million investment in equipment that will boost automation while still maintaining high quality controls. According to Rezuke, the investment addresses the continued struggles to identify qualified labor while at the same time supports the company’s overall plan to grow the business over the next three years. “The addition of this state-of-the-art equipment will increase our overall production by about 30% and improve our overall quality control,” Rezuke explained. “More important, the expansion will not result in any layoffs; in fact, it will allow us to transfer 14 team members to other areas in the production department.”

For other major Canadian manufacturers, being vertically integrated is the key advantage. Such is the case with Lauzon Hardwood, which owns five sawmill operations that feed its flooring operations. That translates to access to more than 2 million acres of the highest quality maple, yellow birch and red oak in Quebec, according to David Lauzon, Jr., director of sales. “We’re the only company here in Canada that has direct access to the forests,” he said, citing a long-term agreement the suppliers made with the Canadian government, which owns the forest lands. “Our sawmill in Thurso alone harvests 15% of all Canadian hardwood that gets harvested in a year. But the process we employ is selective cutting; we do not do any clear cutting. We target only those trees that we are much older and probably will expire over the next 10, 15 years.”

Another factor going in Lauzon’s favor is its flexible production capabilities. For example, its sawmills are configured in such a fashion whereby the raw lumber can be optimized to maximize the widths of the boards based on the desired size (wide vs. narrow width) or end use (i.e., flooring vs. furniture applications). This capability, according to Lauzon, provides an advantage over those suppliers that purchase a greater percentage of their raw materials on the open market. And for a company that offers both solid strip and engineered boards, that makes a big difference.

“When you buy most of your lumber on the market—which is predominantly random widths—you typically get stuck with about 30% that’s 2 ¼-inch, which doesn’t sell as much,” Lauzon explained. “With our system, we only get about 8% to 10% of material that’s under 2 inches wide. That means we don’t have to dump 2 ¼ into the open market just to get rid of it. This method gives us more stability in our raw materials.”

Beyond the sheer quality of the raw material, locally sourced lumber brings with it other tangible benefits for Canadian hardwood flooring suppliers. “As a North American company that specializes in wood, we pride ourselves on creating jobs where we live and sourcing local raw materials,” explained Brad Williams, vice president of sales and marketing for St. Georges, Quebec-based Mirage Hardwood Floors. “Continued locally sourced flooring is good for society, good for the planet and gives customers peace of mind now and for generations to come. We believe we have a positive impact on the health and well-being of people and the environment by using sustainably harvested wood to produce the highest quality hardwood floors made in North America.”

Other Canadian hardwood manufacturers are also leveraging their local supply. “One of our main advantages is our engineered production,” said Julien Dufresne, vice president of sales and marketing, Preverco. “We are fully integrated with our engineered production, and we have slowly been moving away from using imports of plywood for our core and shifting to pine from Quebec and eastern Ontario. In fact, we only use 100% local resources in our product.”

Preverco also prides itself on the expertise of its manufacturing workforce. “We’ve been around since the late 1980s, and the guy who’s running our finishing plant has been here since 1990,” Dufresne noted. “In addition to that, most of our plant managers have been with us for almost 20 years. It’s a very stable environment in terms of management and top positions, which translates to a lot of know-how within the company.”

Ongoing investments

One common denominator across most Canadian hardwood suppliers Floor Covering News interviewed for this feature is the high level of investment companies are making in their operations. Case in point is Mercier Wood Flooring—a pioneer in prefinished wood flooring—which made significant capital improvements in 2022 designed to improve efficiencies in its automation processes. These improvements, according to Bondrowski, covered several key areas of its operations ranging from milling to packaging. “The investments we made last year resulted in a 15% better production rate,” he explained. “And by the end of this year we expect to make even more investments to boost output and capacity.”

Like Wickham, the investments Mercier plans to make won’t come at the expense of its skilled workforce. “We value our people,” Bondrowski told FCNews. “We use automation mainly to help us produce more product, but the people whose roles will transition will move into other positions that are available in the plant.”

Over the past few years, in fact, Mercier has imported labor to bolster its manufacturing workforce. Coming out of the COVID-19 pandemic, for example, the company brought people in from Madagascar—where French is predominantly spoken—to work in the plants in Drummondville, Quebec. “We’re actually going to bring in about 12 more people into the plant from Madagascar to fill open positions at our plant,” Bondrowski said.

Lauzon is also taking a page out of the sourced labor playbook. The company hired more than 50 people—also from Madagascar—to fill its manufacturing ranks, and it’s all in support of the country’s progressive immigration directives. “At first the Canadian government imposed limits of 10% of the total sales force, but they have since opened it up to 20%,” Lauzon stated.

At the same time, Lauzon is supplementing physical labor with technological enhancements, namely automation to expedite packaging and bundling—a labor-intensive aspect of the business—and to improve overall operational efficiencies.

“We have a three-year, $25M investment plan for the business,” Lauzon explained. “In addition to addressing the labor issues, which most companies are dealing with these days, it’s also about automation and using emerging technologies such as artificial intelligence. It definitely makes sense for tasks that are very labor-intensive; here we can put in a machine to do it and then train operators instead of laborers.”

Another area suppliers are devoting investments is in research and development—specifically around alternative core materials to the popular but increasingly scarce Baltic birch. “We are currently looking outside of our normal supply channels to see how well others species test,” Mercier’s Bondrowski explained. “We’re going to make sure we do our testing; it’s a rigorous process. Each plywood product that we’re testing takes anywhere from eight to 10 weeks to get the results.”

Core improvements

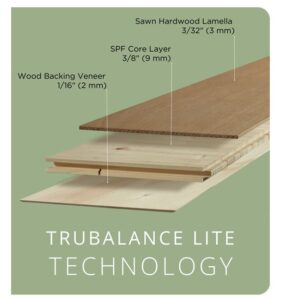

The race to develop alternative core materials is also spurring other major Canadian hardwood flooring suppliers to ramp up their R&D efforts. In the case of Mirage Hardwood—regarded in many circles as the standard bearer in the production of hardwood flooring—that research has resulted in an innovative core structure used in some of its engineered product offerings. Case in point is the company’s new TruBalance Lite technology, a thinner version of its predecessor, which features a unique core technology of real wood lamella measuring 3mm over a locally sourced, 3/8-inch-thick (9mm) SPF (spruce, pine, fir) core layer bonded to a 2mm wood backing veneer. According to Williams, the 3-ply construction makes TruBalance Lite boards more resistant to fluctuating humidity levels that could result in warping or cupping in solid wood boards exposed to the same conditions.

The race to develop alternative core materials is also spurring other major Canadian hardwood flooring suppliers to ramp up their R&D efforts. In the case of Mirage Hardwood—regarded in many circles as the standard bearer in the production of hardwood flooring—that research has resulted in an innovative core structure used in some of its engineered product offerings. Case in point is the company’s new TruBalance Lite technology, a thinner version of its predecessor, which features a unique core technology of real wood lamella measuring 3mm over a locally sourced, 3/8-inch-thick (9mm) SPF (spruce, pine, fir) core layer bonded to a 2mm wood backing veneer. According to Williams, the 3-ply construction makes TruBalance Lite boards more resistant to fluctuating humidity levels that could result in warping or cupping in solid wood boards exposed to the same conditions.

Suitable for installations where ½-inch-thick hardwood is specified, TruBalance Lite offers the ideal overall floorboard thickness for combining hardwood floors with tiles and other flooring materials, the company stated. Moreover, TruBalance Lite can be nailed, stapled, glued or floated over a wood or concrete subfloor, and the product is suitable for installation on, above and below grade—including over radiant heating systems.

Another quality-minded Canadian hardwood supplier that continues to innovate in the area of hardwood core technologies is Opus Floors, headquartered in the Alberta province of Calgary. While the company provides a host of various hard surface products—including cork planks, LVP and laminate, a key focus currently is its lineup of multi-ply engineered hardwood floors.

“The majority of what you see in the market today is a 3-ply construction; we do ours in a 7- or 10-ply construction,” said Vern Verkley, owner of Opus Floors. “Here in Calgary, especially out in the prairie, the climate is brutal and really hard on wood. Three-ply products in this market might expose companies to a much higher risk of failure, but a good wood product has to endure Canadian prairie winters where the temperature can get as low as minus 30 or 40 degrees up here—and that’s not including the wind chill.”

Opus Floors currently offers several different platforms in its engineered hardwood line to accommodate different budgets, applications and end-user scenarios. But even its “entry-level” products, Verkley noted, are by no means sub-standard.

“Even our lower-priced product like the Creek Series is a 7-ply, ½-inch-thick engineered line with a 3mm wear layer in random lengths,” he explained. “It’s a beautifully constructed product. If you want to compare it to some of the other brands, which are typically ½-inch, 1mm wear layer in a 5-ply construction, or 9/16 with a 2mm wear layer—our entry-level is actually thicker than some of the products that others promote as premium.”